Automation solutions for electrified monorail systems (EMS)

Electrified monorail systems (EMS) allow for floor-free, efficient transport and are used in production and in-house logistics.

SEW-EURODRIVE categorizes the automation solutions for electrified monorail systems in EMS safety, EMS advanced,

EMS basic, EMS modular and other adapted EMS solutions.

Solutions for production and logistics

- Powerful drive and application controller

- Reliable switchable electrified monorail gear motors by coupling in the gearbox final stage

- High-performance safety controller for comprehensive safety functions

- Slotted waveguide technology for reliable and stable data transmission in a high bandwidth

- Contactless energy transfer for particularly low-maintenance systems

- Innovative software tools for engineering, project planning, simulation and startup

- Different travel speeds depending on position and load – also possible with SLS/SLP

- Temporarily increasing the speeds for closing gaps

- Adaptive buffer distances

- Safe distance monitoring (SDM®) for a safely controlled distance between the vehicles

- Safe envelopes for applications with lifting

- Synchronization with other systems, e.g. “on the fly” marriage

- Detailed online diagnostics of the vehicles using the MOVIVISION® parameterization and diagnostics software

- Condition monitoring to improve system diagnostics and early failure detection

- Simulation for the entire assembly process – from quality testing to productive operation

- Digital twin of the production system – from OT to IT

- EdgeDevices for data coupling of third-party I/O devices via MQTT

We're here to help

- Our experts know your industry and its requirements

- Our global network ensures we are close at hand, wherever and whenever you need us

- We have the expertise and tools to provide you with the best possible support and advice

The benefits for you

Automation from a single source!

From software, communication and sensor technology to control, inverter and drive technology.

Standardized or customized!

Flexible MAXOLUTION® technology modules for versatility and maximum availability.

Know-how!

With many years of experience, we implement optimized and proven solutions with our customers in international projects.

Always close to you!

With worldwide startup service directly on site – fast and reliable.

Related Topics

Electrified monorail system EMS safety

- MOVIPRO® PHC drive and application controller

- Powerful with integrated frequency inverter from 2.2 kW to 22 kW – usually for the lifting axis

- Other decentralized frequency inverters, e.g. travel and tilting axis, can be connected

- Fast diagnostics via 7-segment display

- Parameter memory for fast startup and device replacement

- MOVISAFE® HM31-B safety controller

- High-performance safety controller for advanced safety functions

- Memory card for fast device replacement

- Safe envelopes for applications with lifting

- DataMatrix code tape and a safe 2D camera system

- Safe position detection

- Slotted waveguide technology

- Safe WLAN communication from the vehicle to the MOVISAFE® HM31-B stationary safety controller

- EMS drives, e.g. the HK series

- Reliable switching thanks to coupling in the gear unit output stage

- Several sizes ensure permitted wheel loads of 2500 to 40 000 N

- MOVIVISION® parameterization and diagnostics software for detailed online diagnostics

- MAXOLUTION® connected software modules

- Digital twin of the production system with high-resolution 3D visualization

- Options

- MOVISAFE® UCS safety module for safety functions with less complexity

- MOVITRANS® contactless energy transfer system

- Keypad for manual movement of the vehicles

EMS safety electrified monorail systems are often used in automotive production:

- As an application solution for heavy-duty EMS:

- In the chassis line

- In pivot mounting

- As an application solution for light-duty EMS:

- In assembly lines, for example for motor, door or cockpit assembly – each with or without lifting as well as optional additional axes

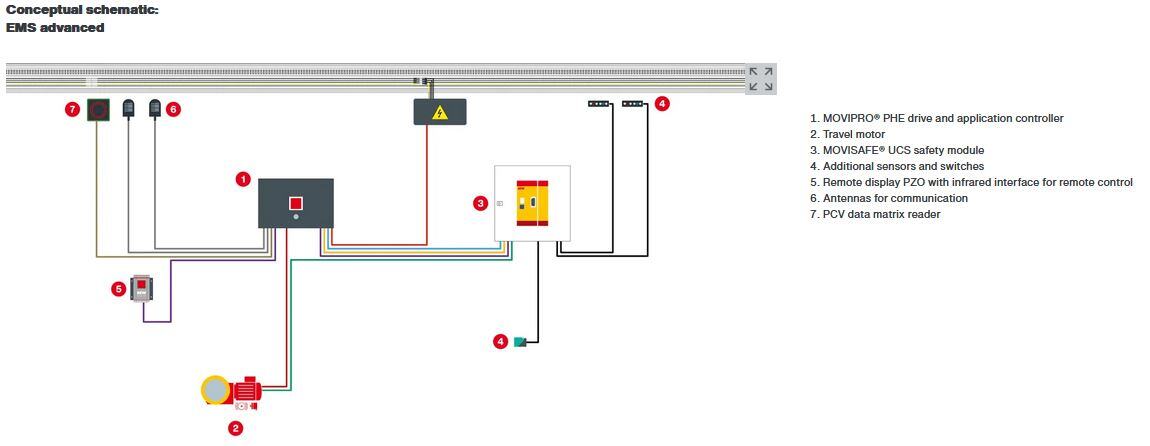

Electrified monorail system EMS advanced

- MOVIPRO® PHE advanced drive and application controller

- Powerful with integrated frequency inverter 1.5 kW – usually for the travel axis

- Other decentralized frequency inverter can be connected

- Fast diagnostics via 7-segment display

- Parameter memory for fast startup and device replacement

- Datamatrix code tape and a 2D camera system

- For position detection

- Slotted waveguide technology

- WLAN communication from the vehicle to the stationary segment controller UHX-65

- EMS gear motors, e.g. the HW/HK series

- Reliable switching thanks to coupling in the gear unit output stage

- Several sizes ensure permitted wheel loads of 2500 to 40 000 N

- MOVIVISION® parameterization and diagnostics software for detailed online diagnostics

- MAXOLUTION® connected software modules

- Digital twin of the production system with high-resolution 3D visualization

- Options

- MOVISAFE® UCS safety module for safety functions with less complexity

- MOVITRANS® contactless energy transfer system

- Keypad for manual movement of the vehicles

EMS advanced electric monorail systems are often used in automotive production as an application solution for light-duty EMS:

- In assembly lines, e.g. for door or cockpit assembly

- For floor-free transport in internal logistics, e.g. for battery, motor or seat tr

Electrified monorail system EMS basic

- MOVIPRO® PHE basic drive and application controller

- Powerful with integrated frequency inverter 1.5 kW

- Control or feedback via half-wave signals on the conductor rails (command and signal rail)

- Fast diagnostics via 7-segment displays and 16 status LEDs

- Parameter memory for fast startup and device replacement

- More detailed diagnostics via PC interface on the controller

- Optical/inductive proximity switch

- Distance monitoring to ahead EMS vehicles

- Half-wave modules stationary

- HTM (half-wave transmission module) for the command rail

- HRM (half-wave receiving module) for the signal rail

- Speed switching via half-wave commands or magnetic switch

- EMS gear motors, e.g. the HW/HK series

- Reliable switching thanks to coupling in the gear unit output stage

- Several sizes ensure permitted wheel loads of 2500 to 40 000 N

- MOVIVISION® parameterization and diagnostics software for detailed online diagnostics

- Options

- MOVISAFE® UCS safety module for safety functions with less complexity

- Keypad for manual movement of the vehicles

The EMS basic electrified monorail system is a cost-efficient application solution with a simple control concept for light-duty EMS.

- It is often used in automotive production:

- For simple assembly lines, e.g. for transporting doors and cockpits

- For simple transport tasks, e.g. for transporting parts/goods

- Other areas of application:

- In the food, beverage and manufacturing industry

- For retrofit in existing systems with the same control principle